Join the iCreate Aerodynamic Blade Challenge to revolutionise fan, rotor, and propeller design across aerospace, aviation, environmental management, and home appliances. We're here to support promising innovators through product development and commercialisation, linking them with customers and investors. Be a part of the next generation of aerodynamic advancements.

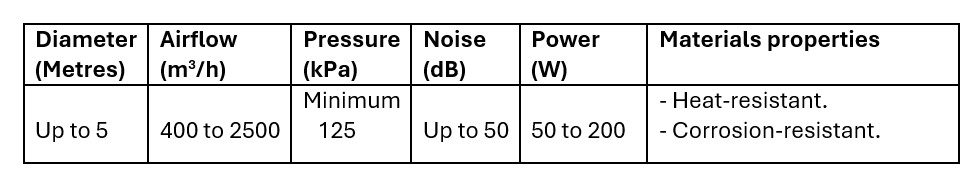

Blades are critical components in various applications where airflow and aerodynamics are paramount, manipulating air gradients and directing airflow efficiently. Innovative blade design is crucial for performance and efficiency. For example, in ventilation systems, blades should maximise airflow while minimising noise and energy consumption. In propellers, blades should optimise thrust and reduce drag, increasing turbine efficiency. From curved and swept-back blades for increased lift, to serrated edges that reduce noise and improve stability, innovations in blade design have revolutionised countless industries. These advancements enhance performance and reduce the power required for airflow - contributing to cost savings and environmental sustainability.

Suggestions for Innovative Elements:

We welcome applications from startups, innovators, academics, and researchers who are ready to showcase their commitment to technological advancement and entrepreneurship. To ensure the viability and impact of the proposed innovations, all applications must be supported by:

Innovate. Transform. Lead the Future of Aerodynamics.